Supporting Projects

Renewing and upgrading equipment facilities and expanding buffer and medium prep departments.

Click on the blocks on the left for more details.

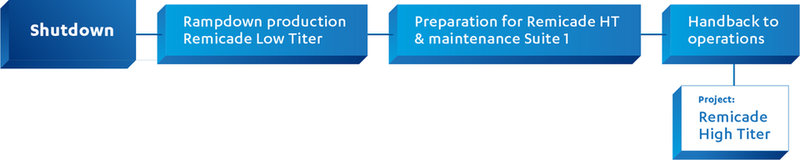

Shutdown

The Shutdown of Cell Culture Suite 1 enables maintenance in the Fementation and Primary Recovery production area's and supports moving to an intensified Remicade production process, increasing output of Remicade with a reduced number of bioreactors.

What & Where?

For the first time in 2 decades, a temporarily shutdown of suite 1 will take place. This enables maintenance activities and is necessary for the transition from producing Remicade LT to Remicade HT. This timeslot will also be used for a MES Software update, for some construction works and other upgrated of surrounding projects. This is a combined effort, all to minimize the production impact and downtime.

When?

The Shutdown is scheduled from 26FEB24 until the end of MAR24.

Project Lead

Buffer Prep Expansion

As buffers are used in production of all products, expanding our production capacity also demands expanding the capacity of the Buffer Preparation department. The Buffer Prep expansion program includes the step-by-step creation of operator filling stations and the construction of two new Buffer Prep stations.

What & Where?

The first step towards operator filling stations is installing a large new 20m3 tank for concentrated NaOH. Next, the automatic dilution of this NaOH is then realized, which enables the filling stations for operators throughout the plant. Later, two additional buffer stations will be installed to increase capacity. The Pre/Post project freed up space for this.

When?

The design phase of this project has started in 2023. Construction of the first phase (NaOH filling stations) of this project have been started and will go live later in 2024. The construction of the second phase (additional BP stations) will start at the end of 2024 and will go live in 2025.

Project Lead

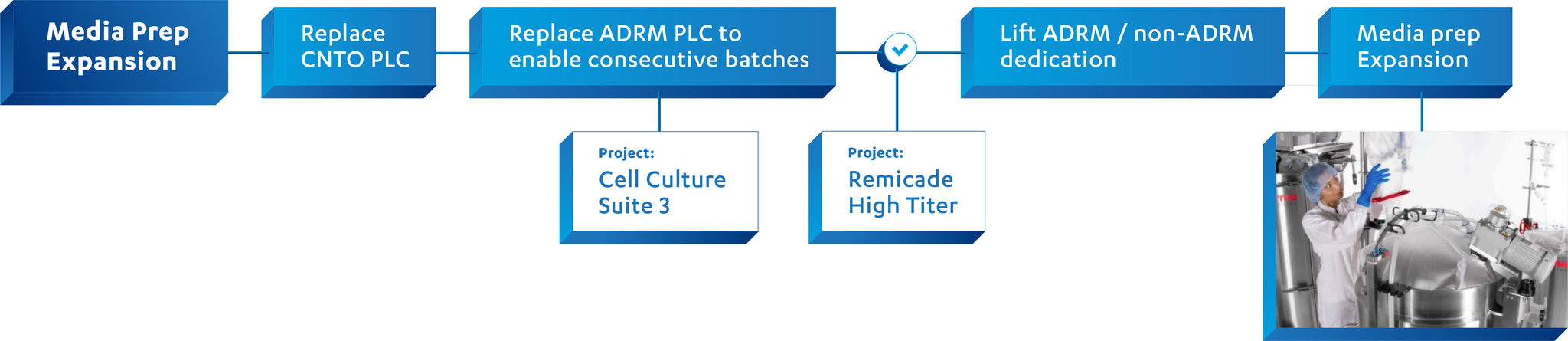

Medium Prep Expansion

In all our production processes, growth medium is used for cultivating cells in a controlled environment. More production then also means a higher demand for the Medium Preparation department. The Medium Prep expansion program updates our current systems and enables an increasing capacity of the number of batches (Media Prep) on a day.

What & Where?

First, the CNTO and old-media PLC will be replaced. Both Suite 3 and the Remicade HT process benefit from the updated PLC systems and depend on this program. Replacing ADRM PLC, will enable two batches being run consecutively thorough cleaning. Additionally, we will lift the ADRM and non-ADRM dedication. This will increase our Media Prep capacity.

When?

The design phase of this project started in 2023. The construction phase will start in 2024, followed by a qualification in 2025. After the construction & qualification, the project goes live.

Program Manager

Gerard Lowe

Project Lead(s)

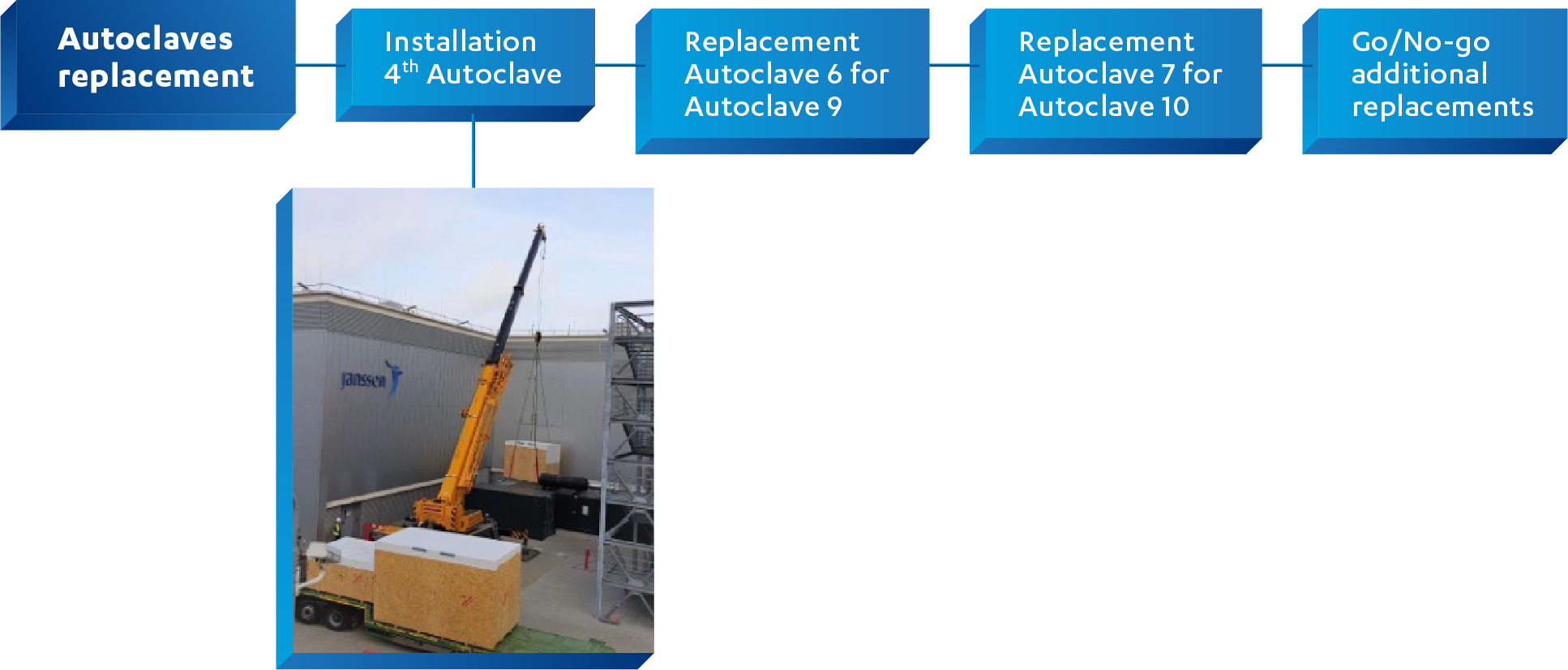

Autoclave Replacement

Autoclaves are used for sterilizing production equipment and tools in the Equipment Preparation (EP) department. To guarantee reliability of EP services, several autoclaves will be replaced. This involves a phased approach.

What & Where?

The first step enabling the replacement of our older autoclaves, required installing an additional autoclave first. This makes it possible to replace the next three autoclaves, one by one, without any impact on our EP capacity. The installation of each autoclave requires an extensive installation & qualification phase, to demonstrate it meets our quality standards.

When?

The first (new) autoclave will go live at the end of 2024, followed by the others.

Project Lead

Washer Replacement

Washers contribute to maintaining high standards of cleanliness, decontamination, and sterilization. Several washers are being replaced (or will be replaced) to guarantee a reliable service. We have been using these washers for many years, the new washers are fully reliable and have a larger washing capacity, without taking more space in our Equipment Preparation department.

What & Where?

The project began with an engineering and design phase. A total of six older washers will be replaced. The new Getinge washers are the same size as the older washers but have larger internal volume. This leads to 1.5 times as many washer capacity in our Equipment Prep department. When replacing the first washer, an installation & validation phase takes place first, which takes a lang time, as all new racks have to be validated.

When?

The first washer has already been replaced in Q1 2023 and almost all racks have been validated..The other washers will be replaced in 2024.